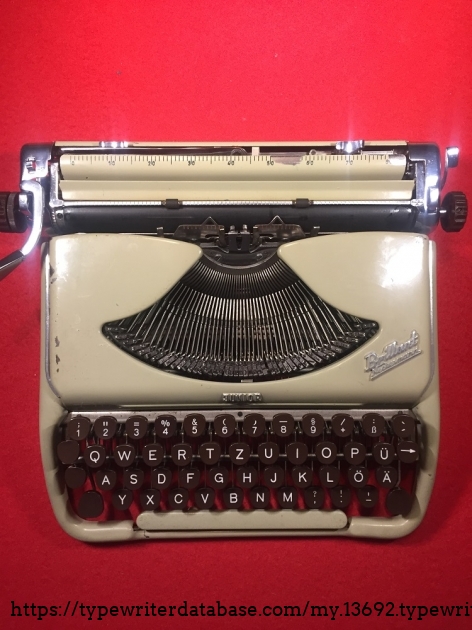

1959 Neckermann (Groma) Brillant Junior #641669

Status: My Collection

Hunter: Paolo Dal Chiele (pdcox)

Created: 03-14-2020 at 06:13AM

Last Edit: 03-14-2020 at 07:28AM

Description:

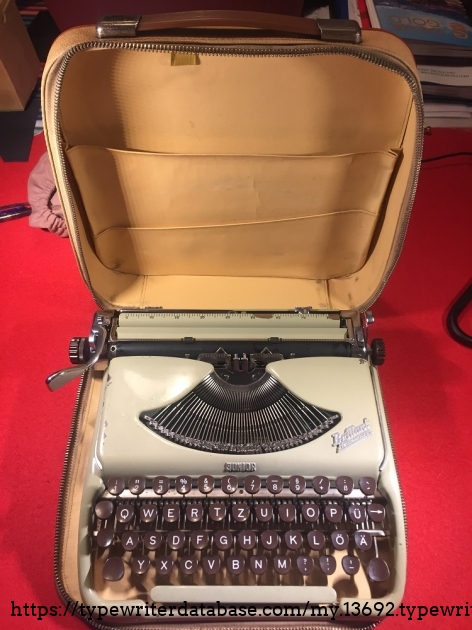

The machine was not working: the main problems from the mechanical point of view were the line space lever not turning the platen (it was moving freely) and the mechanism of reversing the rotation of the ribbon blocked. From an aesthetic point of view, the paint showed clear signs of wear, but overall it was in good condition without rust, and also the bag was in good condition.

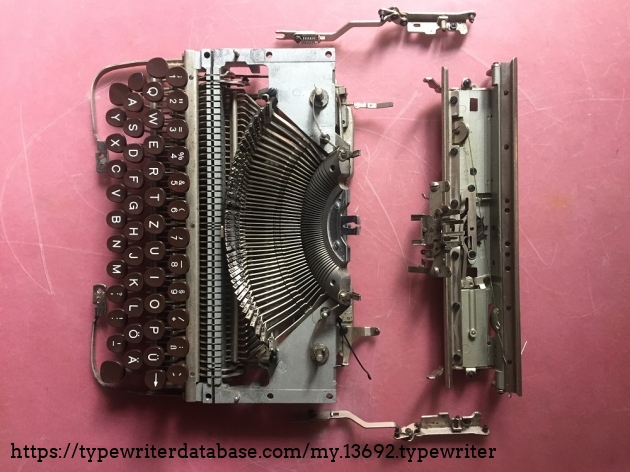

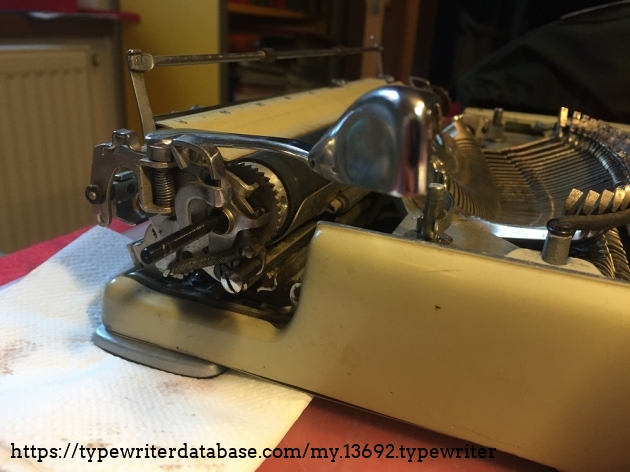

To repair the mechanics I had no choice but to almost completely dismantle the typewriter, which in the case of Junior / Kolibri requires a lot of patience.

In my experience, it is the only machine that has the chassis made up of 4 distinct parts, with many components that are interlocking or interacting by contact, which requires great attention especially during assembly. In addition, chassis and body are connected not only with the fixing screw (10!) but also with four springs, those connected to space bar being particularly tricky to remove and install.

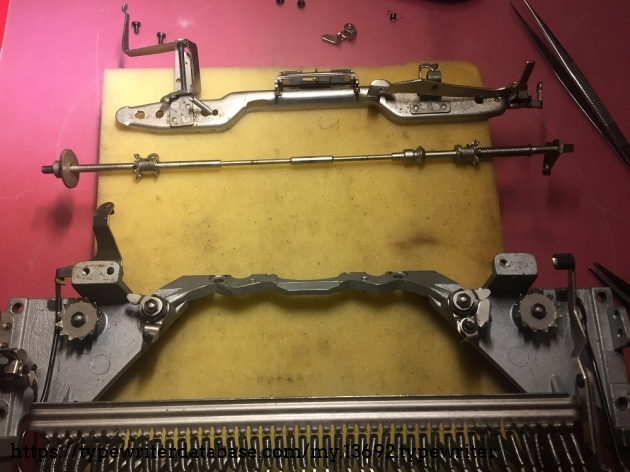

The problem with the ratchet was that some foreign materials entered the mechanism causing the misalignment of the components; repair consisted in cleaning carefully each component and slightly bending the metal tab that hooks the gear wheel.

More complicated was the repair of the ribbon reverse mechanism, particularly because of the very little access to the faulty part.

In a way that I cannot frankly imagine, the rotation axis of one of the two contact flanges that ensure the transfer of the movement from the ribbon was deformed, and all the component of the right mechanism were out of alignment.

Now everything is in good working conditions, and the only problem remaining is the alignment of the type.

Altogether, the Junior/Groma is a very interesting machine: to obtain such a compact size this machine has been designed developing truly brilliant and complex solutions, such as the type bar links, which are not simple bent wires with hooked ends, but formed links with variable section and S-fixing.

If the derivation from Gromina is obvious, it is so re-conceived in every part - for the main purpose of facilitating production - that it can be considered as a substantially new project.

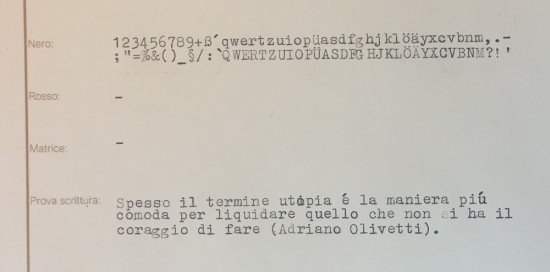

Typeface Specimen:

Photos:

Hunter: Paolo Dal Chiele (pdcox)

Paolo Dal Chiele's Typewriter Galleries [ My Collection ] [ My Sightings ]

Status: Typewriter Hunter

Points: 3242

Interested in historic motoring and vintage cars, I received a typewriter as a bonus when I bought and old off-road car. The previous owner had found somewhere a typewriter produced for the German army and when he sold me the car he gave me the typewriter too. As I learned later, it was a1961 Olympia SM7 Robust..

Of the typewriters I value more character than perfection, the signs that time has left and the stories - or fragments of stories - of those who used them ...

RESEARCH NOTE: When researching the Neckermann (Groma) Brillant Junior on a computer with lots of screen real estate, you may find that launching the Neckermann (Groma) Serial Number page and the Neckermann (Groma) Brillant Junior By Model/Year/Serial page in new browser windows can give you interesting perspectives on changes throughout the model series.