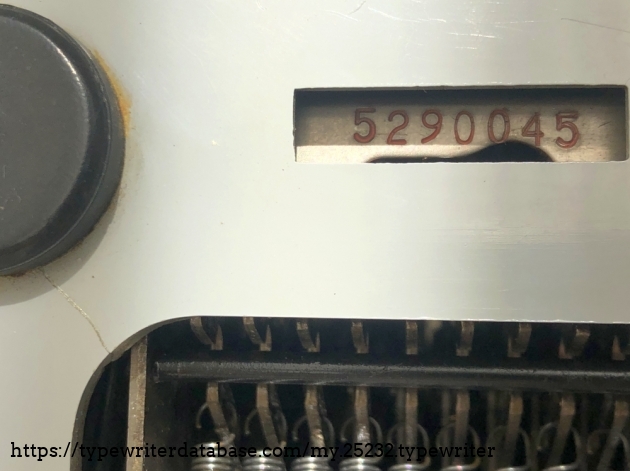

1972 Olivetti Praxis 48 #5290045

Status: My Collection

Hunter: Hein Reinders (heinemaat)

Created: 03-30-2025 at 12:52PM

Last Edit: 05-16-2025 at 04:14AM

Description:

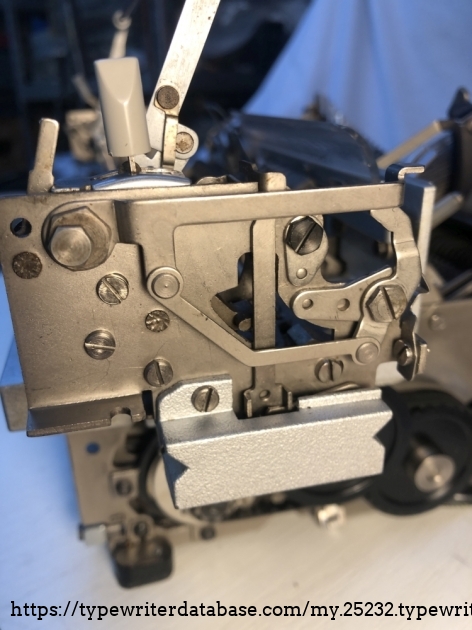

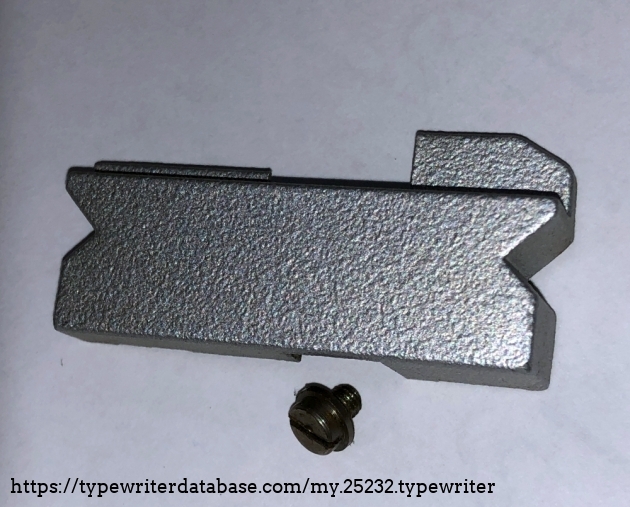

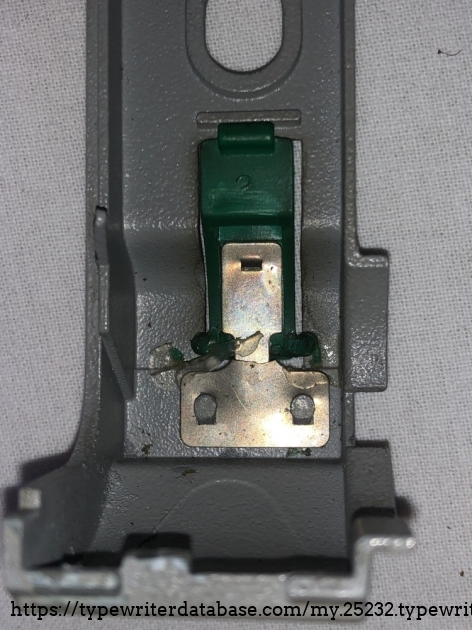

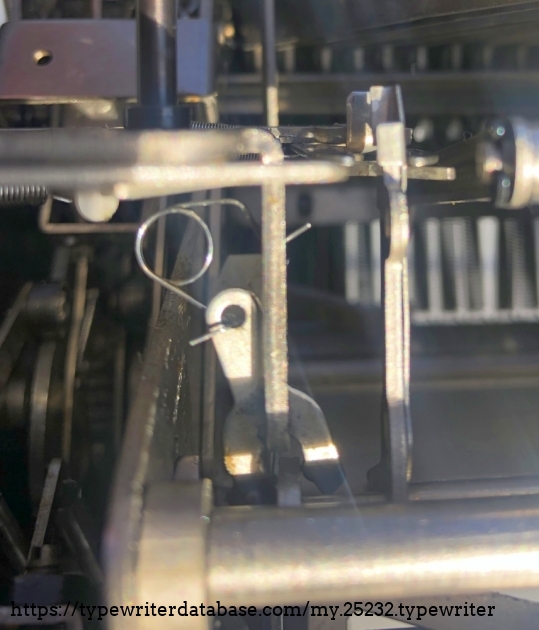

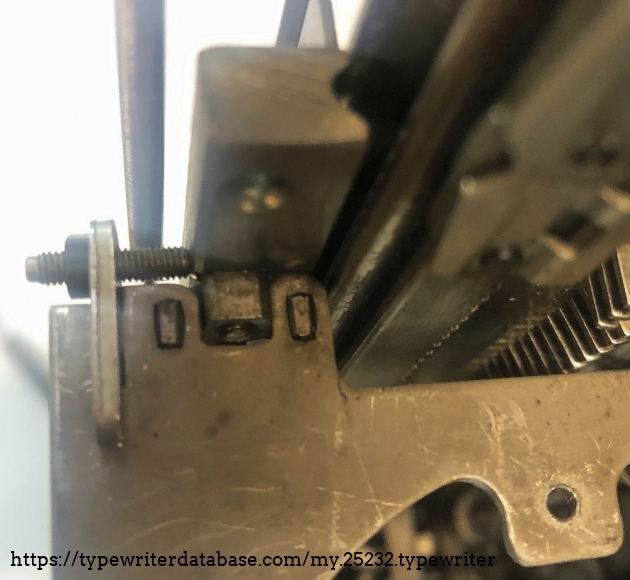

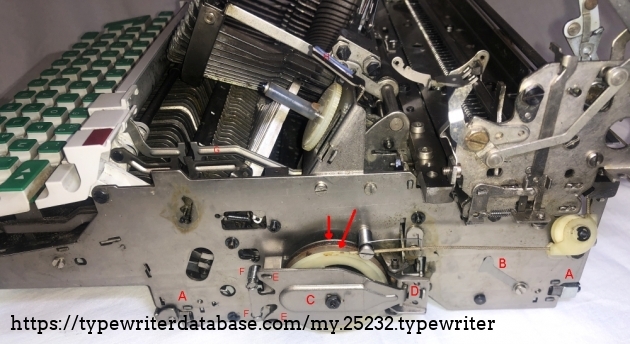

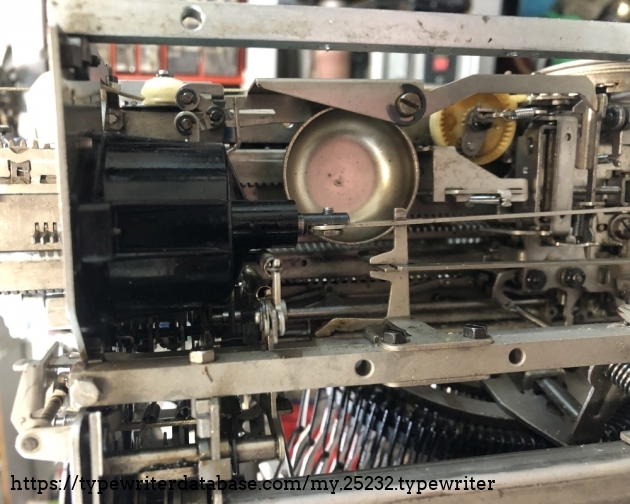

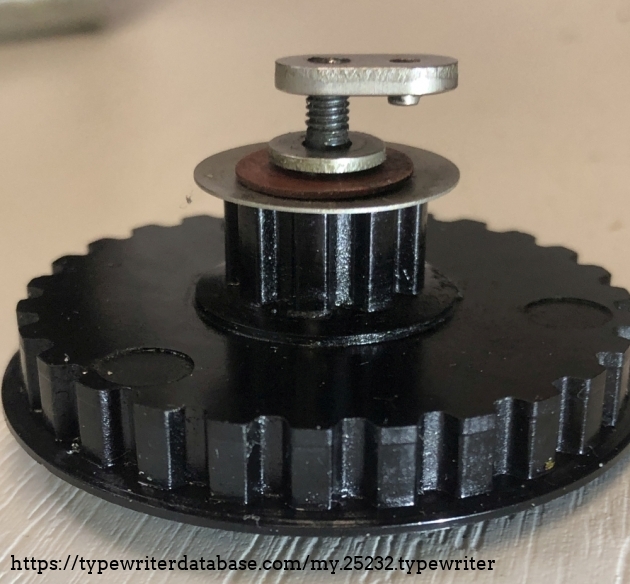

This is my second Olivetti. It was a nightmare to clean and repair. In the end, everything worked fine.

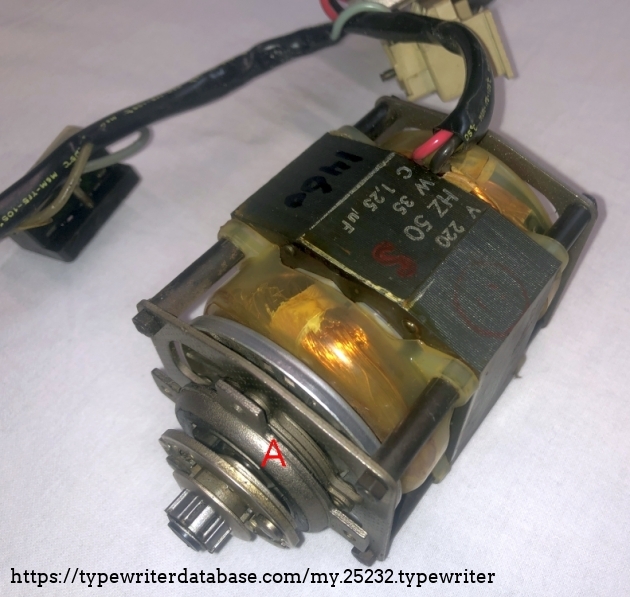

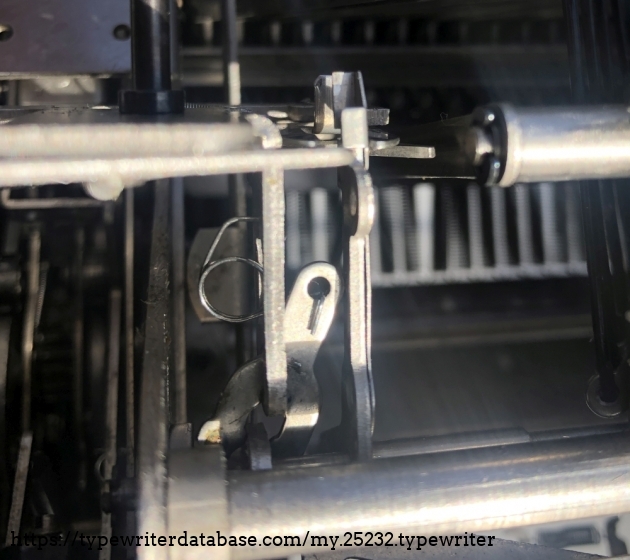

Then it developped a fault: after touching a key it types one time, two times or many times the same character. All key suffer from this desease, Just touching a key lightly can cause a machine-gun result. Or not, sometimes it works okay, for once.

I studied the service doc, tried everything to find a clue. I found no cause and no cure.

Anyone?

I am open to advise..... email hreinder1950@gmail.com

Enjoy the photogallery!

Typeface Specimen:

Photos:

Hunter: Hein Reinders (heinemaat)

Hein Reinders's Typewriter Galleries [ My Collection ] [ My Sightings ]

Status: Typewriter Hunter

Points: 1145

As a retired product development engineer, I am fascinated by the design of electro-mechanical products in which parts move, make noise and, preferably, radiate a little heat. Most preferred are products that are operated by keys, like typewriters, accordeons and pianos.

My genetics and statistics on lifetime expectancy suggest that it is time for me to let you know about the fantastic design, product engineering and manuacturing skills of the generation before mine. I salute mr. Munk for the opportunity that he has created for me to show it to the world. Okay, a bit bombastic.

Comments? Email me at hreinder1950@gmail.com

RESEARCH NOTE: When researching the Olivetti Praxis 48 on a computer with lots of screen real estate, you may find that launching the Olivetti Serial Number page and the Olivetti Praxis 48 By Model/Year/Serial page in new browser windows can give you interesting perspectives on changes throughout the model series.