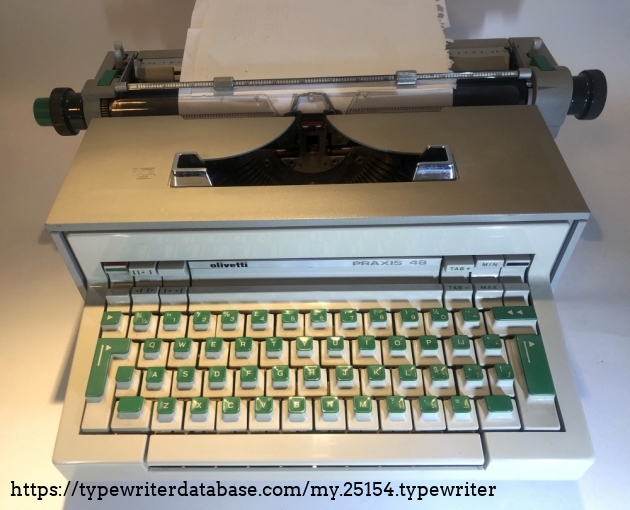

1968 Olivetti Praxis 48 #5167444

Status: My Collection

Hunter: Hein Reinders (heinemaat)

Created: 03-22-2025 at 02:21PM

Last Edit: 04-09-2025 at 02:52AM

Description:

Sottsas made the keyboard protrude from the machine, like the keyboard from a piano, as if you are invited to come and sit with it, even to play it?

But the Praxis48 it is not a piano-forte. It is not that manual tool, that is silently waiting for you to work it.

It is insensitive to the touch. The Praxis 48 is a machine, a typing machine. You must plug it in, switch it on, wake it up and it starts humming.

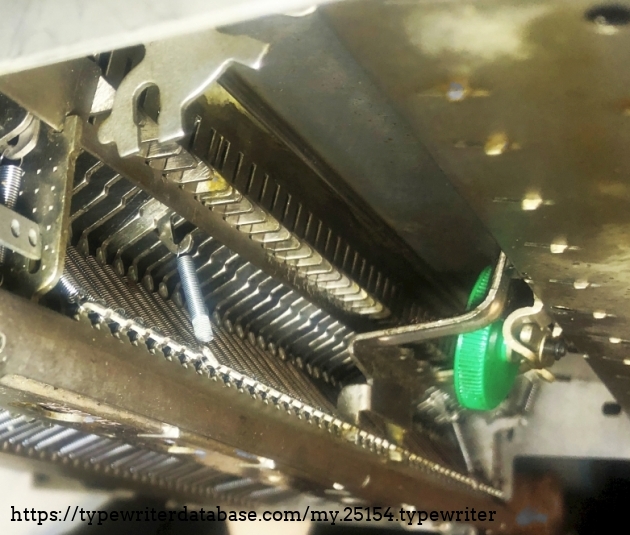

Whether you caress the keys or you hammer them, the keys are merely âon-off-switchesâ. They trigger a mechanism that kicks the corresponding type against the paper. The impact of the types on the paper is governed by the energy stored in one, single, type-spring. It is always this same coilspring that kicks up any typebar after being triggered by its corresponding key.

The typist can choose an âimpression controlâ between normal or maximal via a switch at the right in the 'dashboard'.

After a type-action, the typebar is pulled home by a small coil spring. The tension of each spring can be set (by a service mechanic) to achieve an even print over all typebars.

The typist, as a machine operator is able to adjust the pressure (~25-75 gr) at which the keys all trip from âoffâ to âonâ (green wheel under the keyboard).

The shape of the keys (broad at the bottom, narrow at the top) creates a small contact point for fingers and enough distance between keys to avoid you touching two keys with one finger. Is this by chance or is it intentional?

The row of toggle switches at the top, the full width tab key: different, beautiful, sophisticated, fabulous.

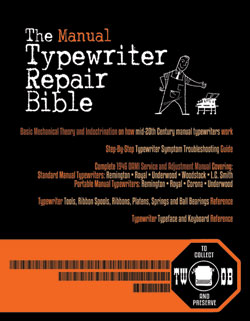

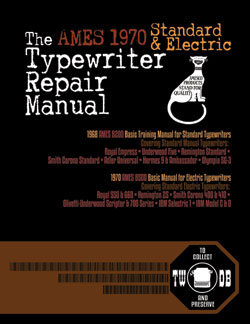

The internal mechanical construction is as impressive as its outside design. The very good repair manual (see link) guides you through the design intend and shows that designing a âtyping-machineâ comes with additional problems over designing a manual âtyping toolâ. Motorising functions obliges the designer to avoid the possibility that the machine will destroy itself. For instance, damage after hitting two keys simultaneously cannot be attributed to the typist anymore. On the upside,the servo-mechanism creates opportunities for adding new functionality, like repeating keys, power shift action and CR/LF via keys on both sides of the keyboard.

Problems

1. The motor in this machine did not make any noise after switching it on.

2. There was a rope with a spring hanging out its back.

The first issue was easily solved: the 200 mA fuse had a blown. With a fresh fuse, the motor ran, no further electric issue. It was just that the segment was now shifting up and down, unstoppable.

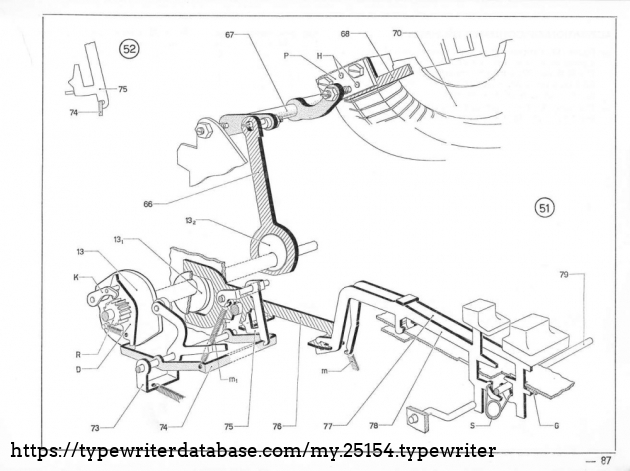

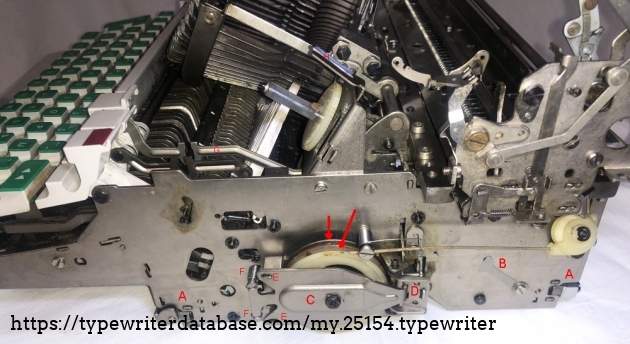

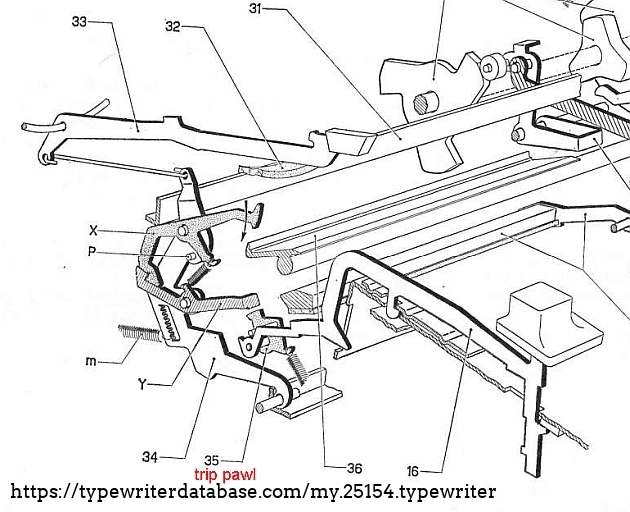

Studying the text and the drawings in the repair manual (see link) was required. Next, you need to identify the actual parts in a forest of levers, cams, springs on the left of the machine in the shift cam group. Access in limited, view is obstructed. Turning the machine upside down helps a lot. Which lever, what pawl could be stuck? Is there a spring loose, or missing? The culprit was identified as âtrip lever 75â. It was stuck, oil had become grease, grease had become gum.

The next problem was the capslock key, that did not come up after pressing the shift key to release it. Clean again.

This is a delicate machine.

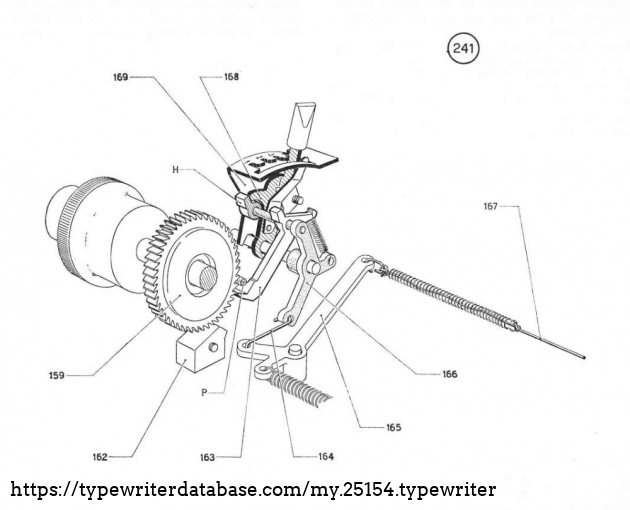

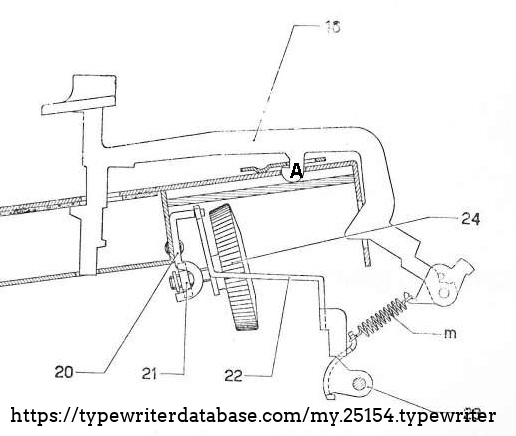

A string and a spring showed up in the back of the machine when the carriage return was done by moving the carriage to the right by hand. It is only with power down and after returning the carriage by hand that the guts hang out. CR worked fine with the power on.

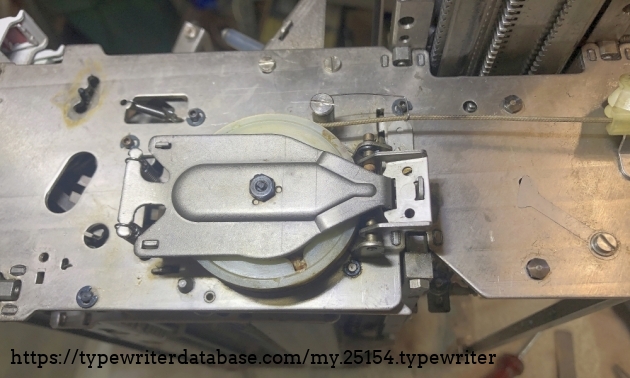

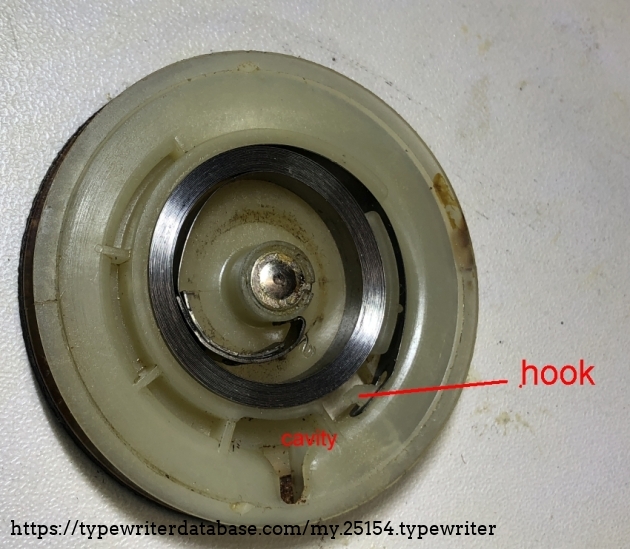

Now, there is a cute little mechanism in the CR coupling that has no other function than to keep that pull-string tight if the carriage is moved by hand. Disassembly, cleaning, winding the tender coilspring in its drum, assembling the clutch set, preload the coil spring to the max (which is not much) and than push the strings knot into the drum, with the carriage in its left most position solved that problem, well, just.

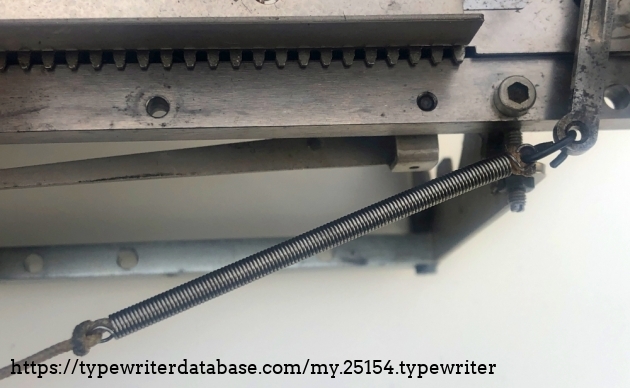

It seemed that the string was a little long and that shortening it would to increase the coilsprings pretension in the drum. There is a tension spring at the LF lever end. A discovery was made: the string is fed through the inside of this tension spring! See gallery. The rope is knotted to the spring at its both ends! The spring only stretches as far as the rope allows it to. What is this? A soft start for the line feed mechanism when the CR-clutch kicks in?

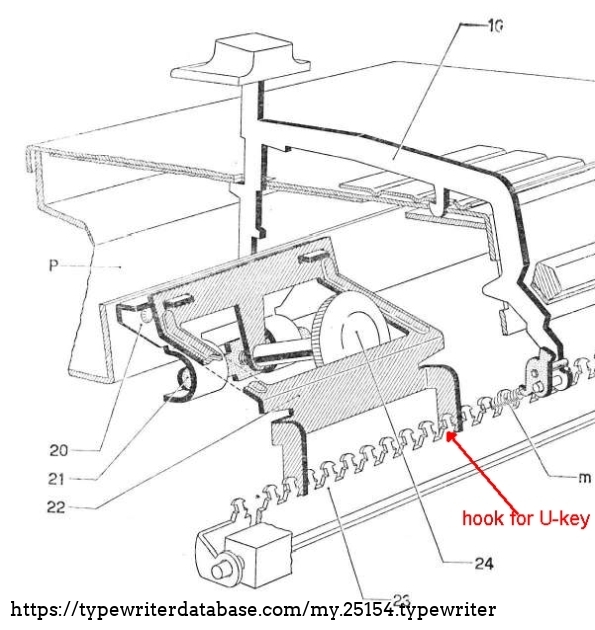

New problem: the letter U/u does not type. Solution: see photos in the gallery

See my gallery on a second Praxis 48 which is still not working properly (coming soon)

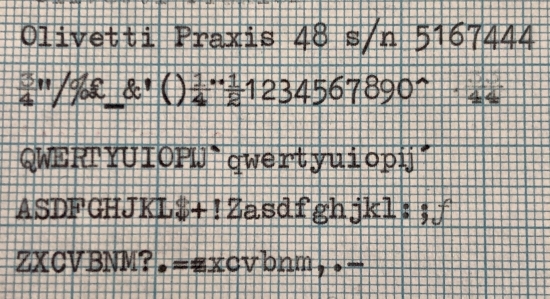

Typeface Specimen:

Links:

Photos:

Hunter: Hein Reinders (heinemaat)

Hein Reinders's Typewriter Galleries [ My Collection ] [ My Sightings ]

Status: Typewriter Hunter

Points: 1145

As a retired product development engineer, I am fascinated by the design of electro-mechanical products in which parts move, make noise and, preferably, radiate a little heat. Most preferred are products that are operated by keys, like typewriters, accordeons and pianos.

My genetics and statistics on lifetime expectancy suggest that it is time for me to let you know about the fantastic design, product engineering and manuacturing skills of the generation before mine. I salute mr. Munk for the opportunity that he has created for me to show it to the world. Okay, a bit bombastic.

Comments? Email me at hreinder1950@gmail.com

RESEARCH NOTE: When researching the Olivetti Praxis 48 on a computer with lots of screen real estate, you may find that launching the Olivetti Serial Number page and the Olivetti Praxis 48 By Model/Year/Serial page in new browser windows can give you interesting perspectives on changes throughout the model series.