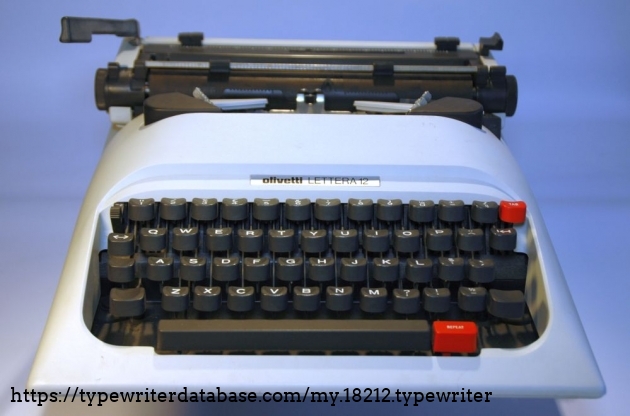

198x Olivetti LETTERA 12 #0489449

Status: My Collection

Hunter: Hein Reinders (heinemaat)

Created: 05-23-2022 at 01:07PM

Last Edit: 01-28-2025 at 03:43AM

Description:

Olivetti Lettera 12 #0489449

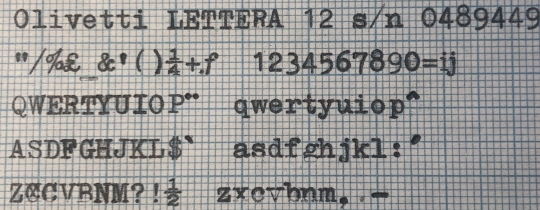

Gallery updated with typeface sample , now that the old ribbon cassette did show up! Rejuvinated with stamp-ink.

But the print is not what it should, working on it.

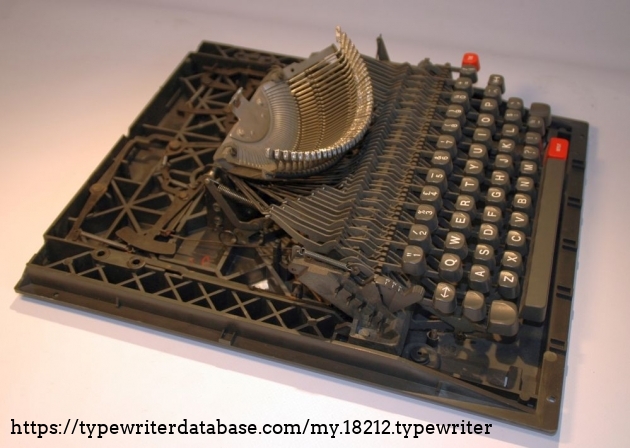

From the point of view of engineering, this is one of the cleverest designs you can make to reduce costs and still suit consumer needs.

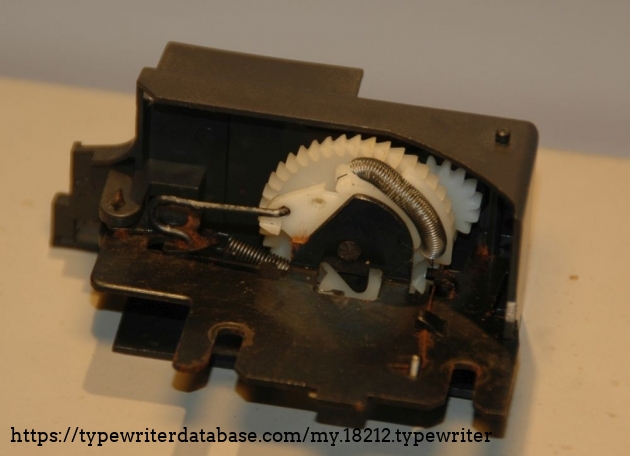

An innovative feature is the ribbon cassette, a breakaway from the traditional ribbon, spools and hopper. For the user there is the advantage of easy ribbon change. For ease of manufacturing you get rid of all the flimsy mechanics of the spool carriers and the ribbon hopper. The hopper function has to be incorporated anew for the cassette, and here the cassette is tilted upward by a ingenuously simple mechanism. The same for the single spool ribbon transport: it hardly be designed in fewer (plasic) parts.

Alas, the ingenious ribbon cassette also means the end for my machine: the world is out of cassettes. If I only had an empty cassette, I would have it refilled it gladly.

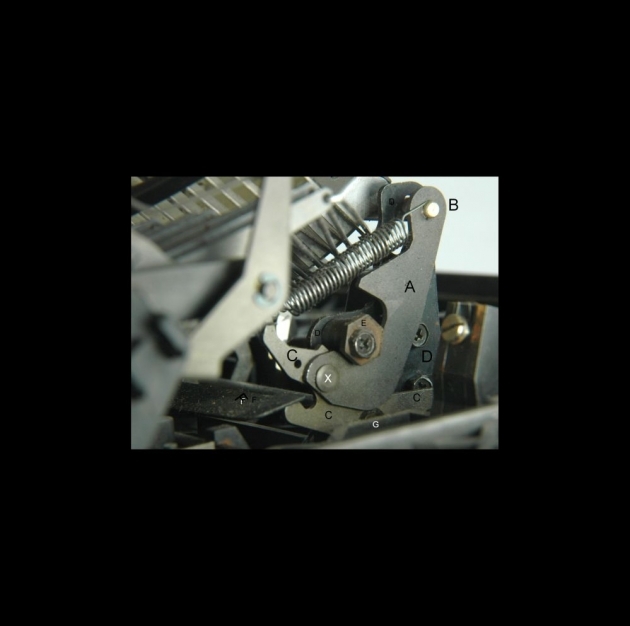

The machine is a design marvel in many aspects. Everything that can be done to reduce cost is done.. Each of the 44 type-mechanism consists of a type arm, a puling wire and a typebar, nothing more!

There is a comb with leaf springs over the full width, the teeth of which push the typearm back after being pressed. So the are no 44 individual coilspring to be assembled.

There is a bar over the full width that is pushed down at a any key stroke. It actives the ribbon advance. The bar is preloaded upwards by a spring and threbeby doubles as type-forces adjustment: the spring can be adjusted by a toggle swich to your preferred amount of extra resistance while typing.

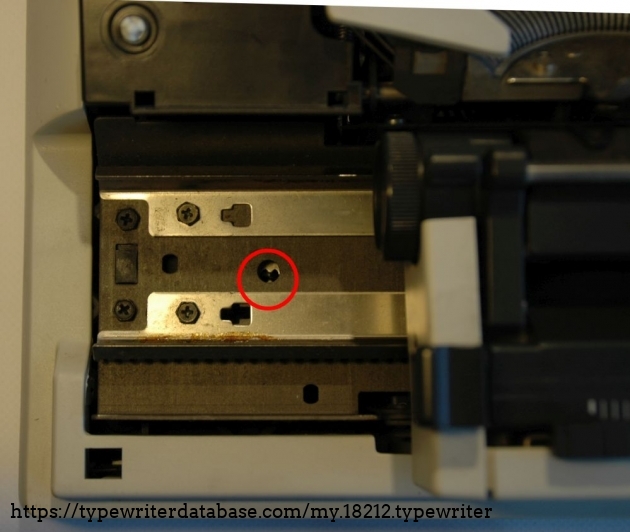

The type-headrest is in steel (see photo). The ‘pillow’ is a rubber tube that is assembled over a steel wire. It is only after this assembly that the wire is spotwelded to two brackets. How else could the rubber tube be assembled?

The type-headrest doubles as a cover over the segment-bearing-wire ends.

The segment seems to be a casting in an aluminium-zinc alloy. The slits that guide the type-arms in are machined, as is the channel in which the semi-circle bearing-wire (?) is held.

Most parts in the carriage are in steel. The covers are in plastic. The side panels hold the back panel in place and are secured with a single screw

It is in plastic unless metal is unavoidable for strength, wear or stiffness. The following items are in steel: the type-arms, the typebars, the segment, the line-feed mechanism and the carriage frame, where this frame has separate stainless linear bearing liners bolted to it. All type-, arms are mounted and guided in slits in a separate bearing-casting that is screwed onto the frame, in the same time securing the levers for caps and spacebar.

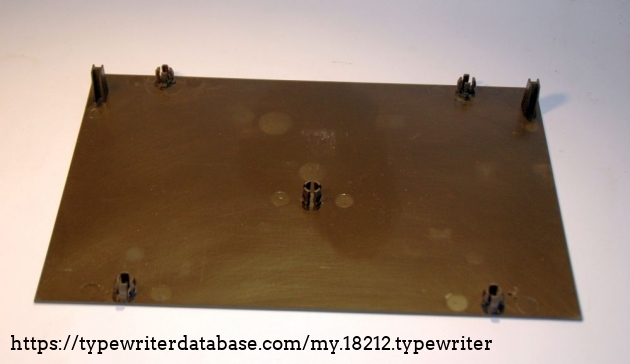

The cover, the chassis, the bottom cover, the springmotor-drum, the carriage panels, all knobs and levers are in plastic.

From a part-count point of view: there are few fasteners (no screw bottom cover, two screws for the top cover, single screw in each carriage side cover)

The carriages module can be removes after loosening four screws ), The spacebar repeat (machine gun) is of an extreme simplicity.

Such design that was used extensively in mass-produced products. Combine functionality in plastic parts (snap fit assembly). It did reduce labour costs and the consequence was unavoidable: the West is not able to produce consumer products anymore, not even if it wanted to.

The cover can be removed after remoning the covers from the carriage (two screws)

The cover can also be removed after removing the carriage (four screws). Assembling the carriage is quit a nuisance: many levers have to be aligned, a guide pole on the back of the segment is a help.

Typeface Specimen:

Photos:

Hunter: Hein Reinders (heinemaat)

Hein Reinders's Typewriter Galleries [ My Collection ] [ My Sightings ]

Status: Typewriter Hunter

Points: 1145

As a retired product development engineer, I am fascinated by the design of electro-mechanical products in which parts move, make noise and, preferably, radiate a little heat. Most preferred are products that are operated by keys, like typewriters, accordeons and pianos.

My genetics and statistics on lifetime expectancy suggest that it is time for me to let you know about the fantastic design, product engineering and manuacturing skills of the generation before mine. I salute mr. Munk for the opportunity that he has created for me to show it to the world. Okay, a bit bombastic.

Comments? Email me at hreinder1950@gmail.com

RESEARCH NOTE: When researching the Olivetti LETTERA 12 on a computer with lots of screen real estate, you may find that launching the Olivetti Serial Number page and the Olivetti LETTERA 12 By Model/Year/Serial page in new browser windows can give you interesting perspectives on changes throughout the model series.