Introduction.

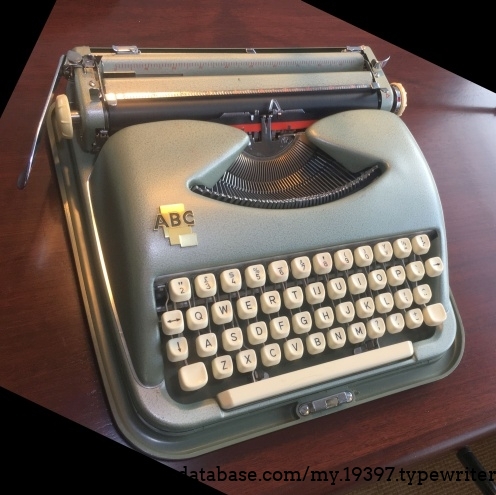

This ABC belongs to Mikal Stet, a collectioneur of fine typewriters.

It is a beautiful machine, full of costly details, like the diecast housing parts and the shiny stainless distance pieces under the cover.

Sadly, it had severe problems. The carriage did not move, the escapement and the backspace key were not working.

The ink ribbon was not transported to the right.

See a description of the repair as long texts under the photo's.

For a good view from the bottom, the machine was lifted from its bottom plate.

For an unobstructed view from above, the platen and the paper guide (that holds the five rubber rollers) were disassembled.

Still, it was hard to catch the catch on camera, for a picture of the shape of it's teeth.

All texts have been reviewed by Laurenz van Gaalen

The escapement.

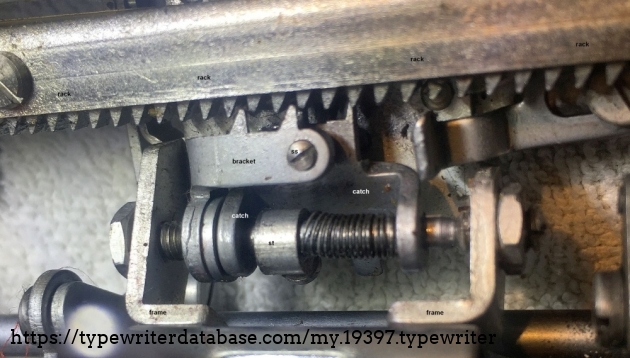

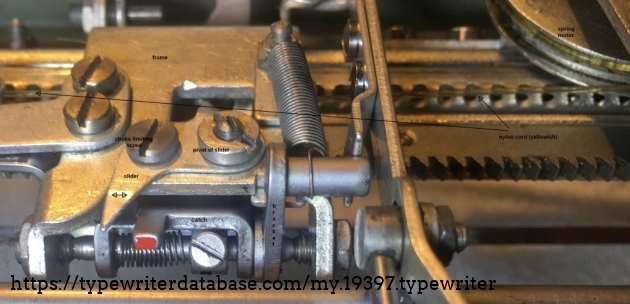

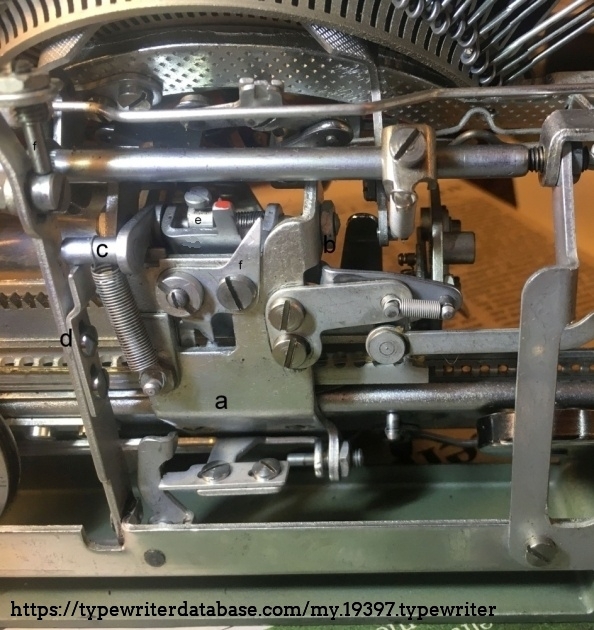

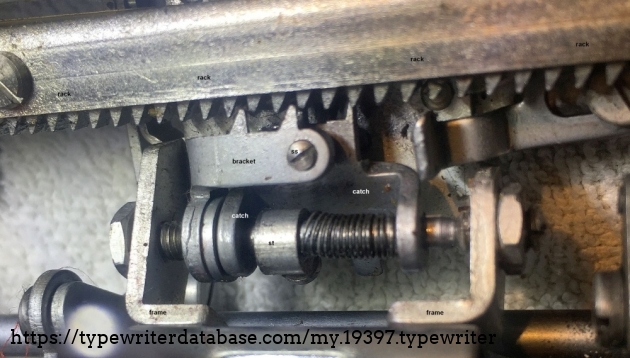

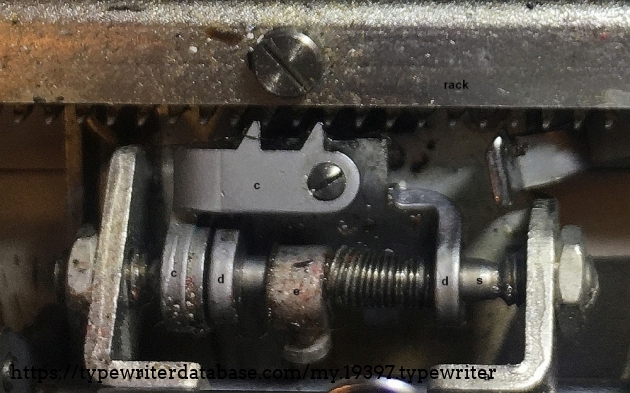

On the mainframe of the ABC there is a stationary frame. There is an escapement bracket with an arbour pressed on to it. The arbour pivots in two thrustbearing set crews (fulcrum screws). The bracket has two teeth. In idle state, the two teeth stand free from the rack. The bracket can be rotated in its pivots by pressing the spacebar or any key. In that case, the the two teeth will sink into the rack’s teeth thus preventing the carriage to move to the left.

There is a catch with two teeth that can slide over and rotate around the arbour. In the photo, one of the two teeth is visible. It is hard to see that the two teeth on the catch are wider at their bottom than at their top. Compare the width with the teeth on the frame. There is a tiny spring, coiled on the arbour. The spring has two functions: it pulls the catch to the right against a stop (st) and it will rotate the catch’s teeth up against a stop-screw (ss) if it gets a chance to do so. The little spring is sometimes overruled by higher forces, as we will see later.

When the spacebar or any key is pushed down by the typist, the cycle begins. The action is described here in slow-motion. At first, the spacebar sinks the bracket’s two teeth down to engage into the rack from the top. Since the teeth of the bracket and the catch are aligned, there is hardly any force needed. Now the bracket is doing what the catch was doing until now: prevent the carriage to move under the tension of the spring motor.

When depressing the space bar further, the bracket is moving down further, and pushing the catch’s teeth out of engagement with the rack, freeing them up below the rack. Now the catch does its trick: under the influence of the spring, it jumps to the right against its stop (st). And, as far as it can, the catch turns its two teeth up behind the rack’s tooth that it was blocking before. All this thanks to the little spring on the arbour (s).

We are not done with the slow-motion action: we have yet to release the spacebar.

The spring motor is pulling the carriage to the left as it always does. The carriage did mot move yet since the bracket is securing it in place.

When the typist lets the spacebar come up, the escapement bracket will lift its two teeth out of engagement with the rack’s teeth. Now the carriage starts moving to the left. The catch was already behind the next tooth of the rack, or it will soon be, now that the rack starts to move left, which fully opens a gap for the catch to engage before the next tooth of the rack. With the catch engaged, the carriage will move further to the left but it will not get very far: after 2,2 mm pitch of the racks teeth, the catch will hit the brackets side wall, the bracket will stop the carriage before it gains any speed.

Sigh. The carriage travelled 2,2 mm and it took 300 words to describe the voyage. That is 7 micron per word, truly a slow motion….

In the original machine at hand, the stop (e) allowed the catch to move 2,4 mm to the right. After readjusting the stroke to 1 mm it still works fine. We do not see a reason to have a larger gap.

On the photo in the right upper corner you see the hook that is waiting to reach into the gear rack if a backspace action is called upon.

The escapement during carriage return (CR)

What should happen? At the manual action of pushing the carriage to the right, the carriage should move freely, and it should stay put as soon as pushing action stops.

When the carriage is forced to the right by hand, the catch’s two teeth are pushed out of engagement with the rack by the skewed shape of the left side of the two catch’s teeth. After sliding against its stop on the arbour, the catch will bow down for each tooth of the rack and shoot into every gap between the teeth of the rack. This will result in a clicking noise, in mediocre machines. Not so in this ABC. The ABC escapement has a feature to prevent wear and noise from this rattling at CR.

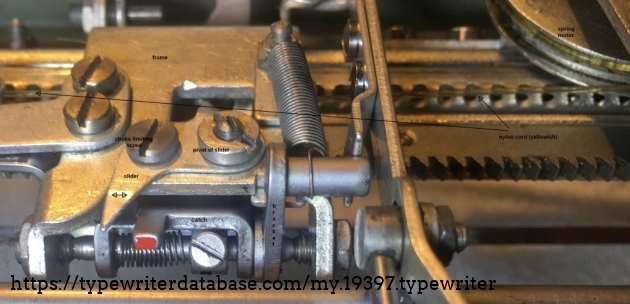

There is this quirky part, here called the glider. It looks as if it had a traffic accident but it is carefully designed.

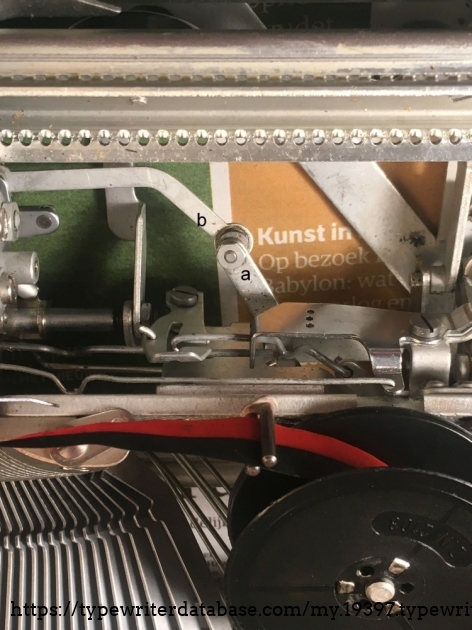

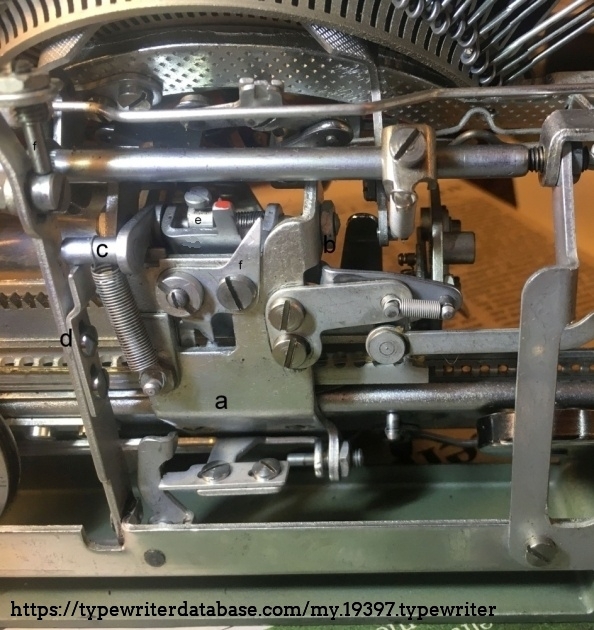

This delicate part (see photo) pivots around cylindrical nut on the bracket. This nut has two slots (and an adjustment screw in its centre). There is a second screw that guides the glider part and limits its rotation angle. The glider has two legs. They reach under the frame. The nylon cord of the spring motor is pinched lightly between the legs. Seen in the photograph, the carriage moves to the right when typing, the nylon cord causes the slider to turn clockwise against its stop. The sliders top end does not interfere with the catch (with the red top), the catch is free to move up after each typing action and catch the rack.

See next photo.

When the carriage moves to the left (at CR and backspace), friction between the nylon cord and the slider’s legs pulls the slider anticlockwise. Now the slider will touch the catch’s tail (with the red dot), enough to prevent the catch from rotating its two teeth into the racks teeth. Thereby, there is no rattling noise at CR.

When CR is completed, the glider stops touching the catch and the catch can do its job: stopping the carriage from going to the left.

It is a good thing that the slider prevents the catch from biting its teeth in the racks teeth, unless it is done when you need the catch to catch the rack, for instance after CR or after a backspace operation. In those latter cases you want the slider to be out of the way.

The backspace key operation

What should happen? When the typist has hit and released the backspace key, the carriage should have moved to the right by one pitch of the rack.

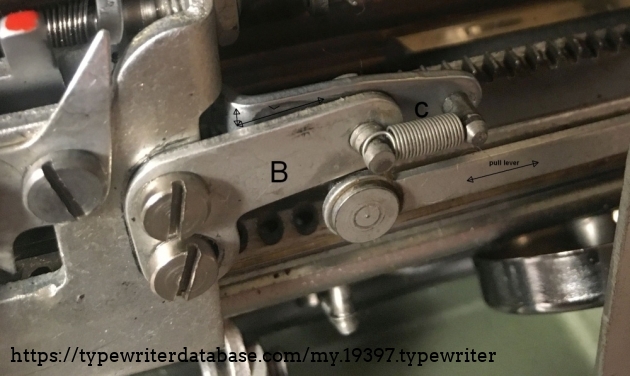

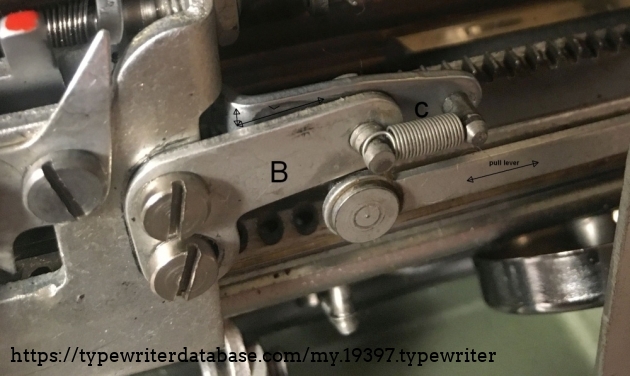

There is a hook C that is activated by the pull lever. When the backspace key is pushed down, the first movement of C is to engage its hook into the teeth of the rack.

After hooking in, move the pull lever further to the right, is to pull the carriage to the right for (more than) one pitch. During this movement of the carriage, the catch will initially move along with the carriage until it hits the stop on the bracket’s arbour. Then it will bow down, by the inclined shape of the two teeth of the rack. This shape is hard to catch on camera.

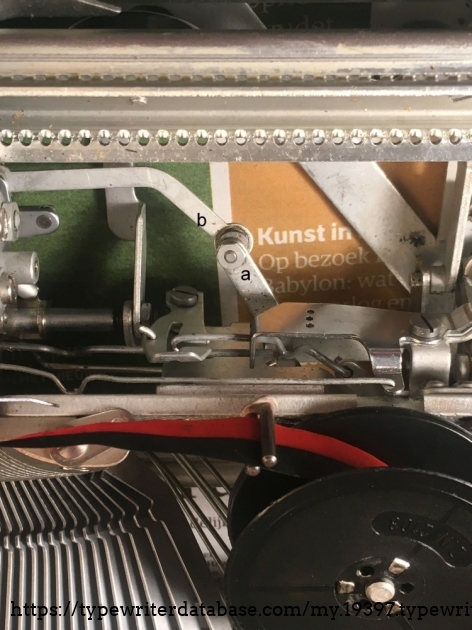

The distance that the carriage moves to the right at backspace should be more than one pitch. The hooks pivot point is on member B and it can be adjusted to have the hook just free of the rack in steady state. The pull lever is adjusted by an excentre on the pulling member. See the photo with lever a and b , a view from the top of the machine. This latter adjustment seems to work on the length of the pulling stroke.

These two adjustments are not independent of each other. You may fiddle around with them for some time.

When the backspace key is released, the catch’s two teeth must rise in the back of the tooth n-1 (to the left of tooth n) to stop the carriage when the backspace key is released. Otherwise, there is no backspace.

The ominous slider may hinder the catch in engaging its two teeth in the rack in time.

It is okay to hold the catch away from the rack when the carriage moves over a substantial distance to the right, as in a full carriage return. At backspace however, there is only a single step to the right. And here, the slider should not impair the catch. A way to achieve this is to optimise the pull-lever action as far as possible to the right, using the two adjustments just described. Then, upon releasing the backspace key, the nylon cord pulls the slider out of the way of the catch in time.

When the backspace key is depressed, the first move of the pull-lever is to hook into a gear of the rack. For maximal effectivity of the backspace key, it may be required to adjust the position of the pull-lever relative to the rack so that it hooks in just behind tooth n of the rack. This is done by moving the complete escapement to left or right by adjusting both bearings (fulcrum screws) of the escapement.

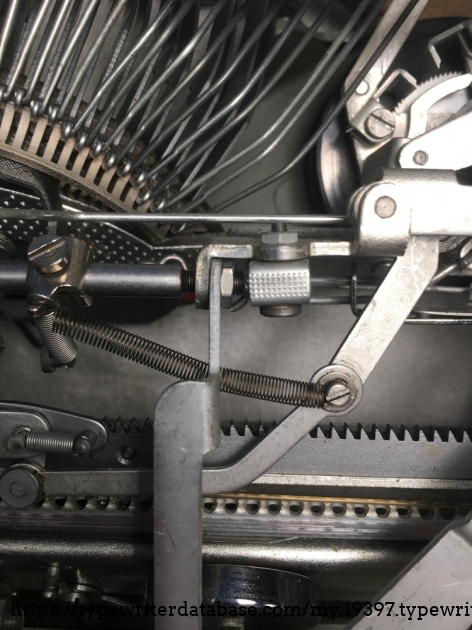

A second optimisation is to place the hook C (see the third picture in the upper right corner) as close as possible to the rack. When trying to be as close as possible abd still preventing collision you may find that the safe distance is unacceptably large, due to slack in the linkages from backspacebutton to hook C. We added a spring that securely pulls hook C to its home position, see the next picture.

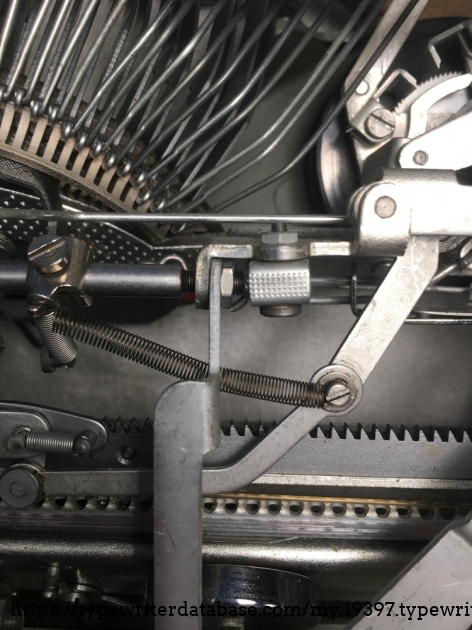

An added spring to take the slack out of the home position of the backspace linkage

The carriage.

The ABC carriage has a gear rack with a tooth pitch of around 2,2 mm, pivoting from the left and right carriage ends. The rack can be retracted away from the escapement by pulling a lever at the right side of the carriage. (When pushed, the lever doubles as a paper release lever.)

A suitable meshing of the rack with the escapement can be found by adjusting the excentre in the photo.

With the lever fully pulled forward, there should be no grinding sound when the carriage moves to the left.

In the case at hand the rack did engage the escapement too deep. The carriage was hard to move and a grinding noise occurred.

We found this adjustment is very difficult to do. It is hard to tighten the screw without rotating the excenter. It is hard to find the optimal position of the rack.

The point of rotation of the rack is ill chosen. It moves "up and down" and "in and out" at the same time.

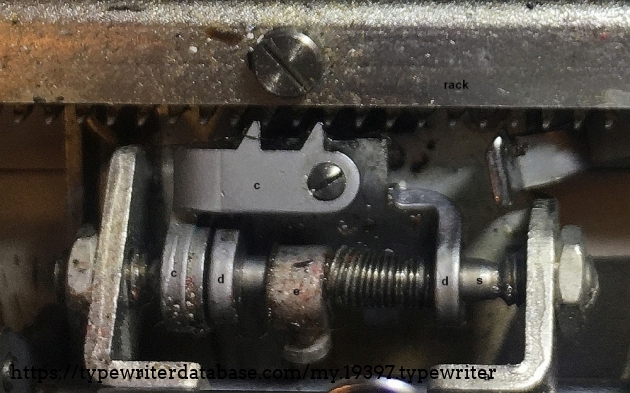

This last picture can be used to illustrate an adjustment of the space bar mechanism.

At (d) you see two srews that determine when the escapement trips while pushing the spacebar down. It should trip just before the spacebar reaches its mechanical stop. In this machine that adjustment was fine, luckily, the two screws are hard to get to.

The next adjustment is the screw (f) in the upper left corner. This screw determines the moment when type arm trips the escapement. In slow motion, that may happen some 10 mm (3/8") before a type hits the platen. When hammering the keys you pass that tripping-point before you know it. Sadly, the upper keys have a more direct response to the touch than their lower row keys have. The lower rows feel spongy. Again, to get it right is a nuisance.

Conclusion

At the start, there were too many variables in play to understand the design of this mechanism.

Not understanding what purpose it served, we simply disassembled the glider from the equation.

Then, the rack, the escapement and the backspace functions were optimised as described. Everything worked fine. There was a nice clicking sound of the catch hopping at CR.

So, what is this glider for? It was designed with care: in the production process of stamping this partr, the legs are rounded to avoid scraping and wearing the nylon cord. Nobody would go to that length for no reason.

The slider was reinstalled and indeed, as expected, at CR, there was not the slightest rattling of the escapement anymore. We found no other added value of reinstalling the slider. The conclusion is that the function of the slider is to overcome noise (and wear) of the catch at carriage return.

So all seemed well.

Until we started to type the typeface specimen. The lower row of keys did not trip the escapament properly . We touched an adjustment: than the backspace failed. Do it all over again. And this is not an easy machine to dis- or assemble.

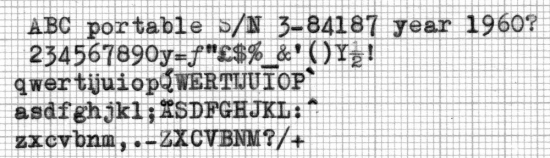

All's well that ends well, the machine is functional again and now there is a typeface specimen

Status: Typewriter Hunter

Points: 1145

As a retired product development engineer, I am fascinated by the design of electro-mechanical products in which parts move, make noise and, preferably, radiate a little heat. Most preferred are products that are operated by keys, like typewriters, accordeons and pianos.

My genetics and statistics on lifetime expectancy suggest that it is time for me to let you know about the fantastic design, product engineering and manuacturing skills of the generation before mine. I salute mr. Munk for the opportunity that he has created for me to show it to the world. Okay, a bit bombastic.

Comments? Email me at hreinder1950@gmail.com