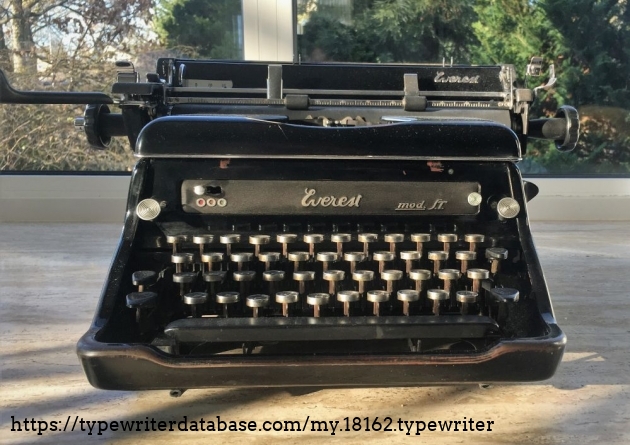

1952 Everest ST #210407

Status: My Collection

Hunter: Hein Reinders (heinemaat)

Created: 05-18-2022 at 04:35AM

Last Edit: 01-11-2025 at 12:18PM

Description:

This Everest model S.T. was manufactured in 1952 (or 1953, see photo) and it is a remarcable design.

Its outer shell is made of 3 mm gauge steel sheet, that is four times the gauge of car body tinplate. The back cover is a massive aluminium casting, and it better be sturdy since it is mounted by two nuts to the machine at the bottom only, freely overhanging the rest. Okay, it has logo casted in beautifully, but when raising the machine, it is advisable to grab under the right and left side, rather than under the front and rear.

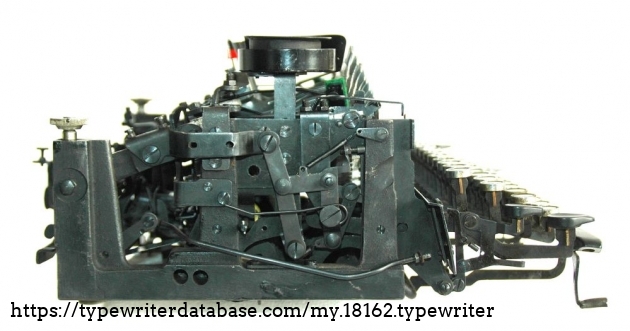

The mechanism is hung from a cast iron frame, with a few aluminium cross members. The machine weights a hefty 15.1 kg, so, if your desk allows, it is a truly desktop typewriter.

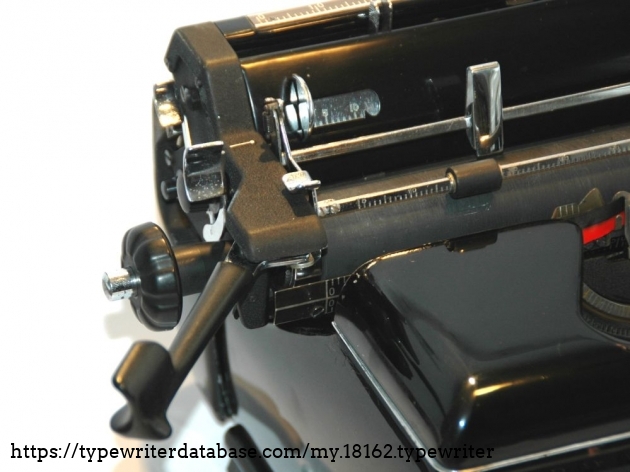

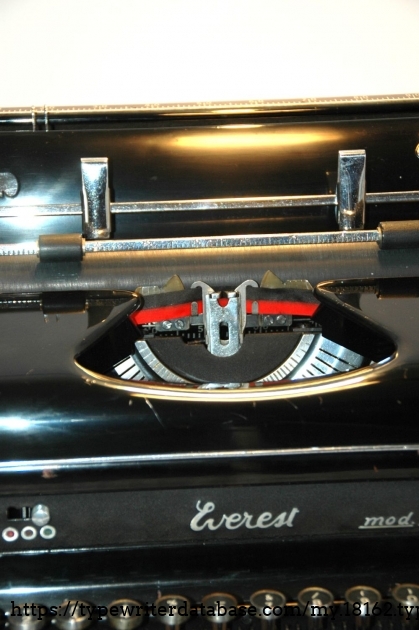

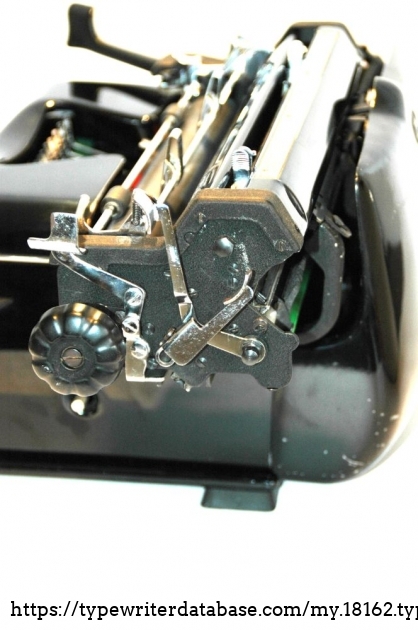

The type-arm pull-rods are pivoted in a battlement shaped casting, see one of the photos, The pull-rods are in two parts, one with a corkscrew end, the other with a hooked end, twisted together.

Is this for length-adjustment? Is it for dampening the touch?

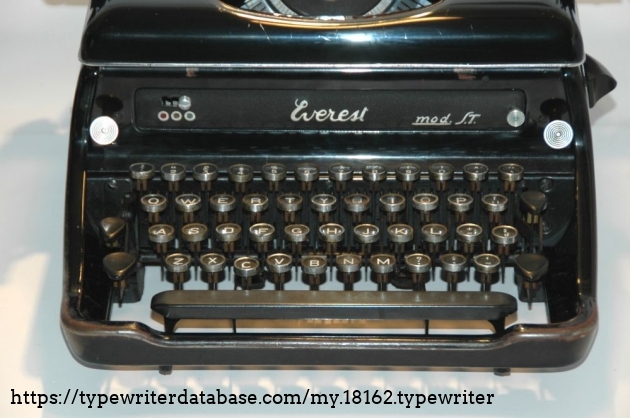

Apart from the (low quality-) chromed parts, all the mechanics are in black.

Standing on our windowsill, it is a Black Pearl.

That is to say, the cleaning of this machine required some effort. A few rubber dampening parts had fluidised and came dripping all over the mechanics. Its former owner may have been a talented and tormented author that sadly died of lung cancer before his masterpiece was finished: the machine required ten times cleaning its body parts before leaving no nicotine traces anymore.

On the right there is slider which untangles type-arms if they got stuck.

There is no automatic ribbon reverse. There is a button on either side that can be pushed to change the ribbon transport direction. The buttons can be turned to manually advance the ribbon. You may be tempted to pull the button: do not. You will only hold the button in your hand. This is a no-good design.

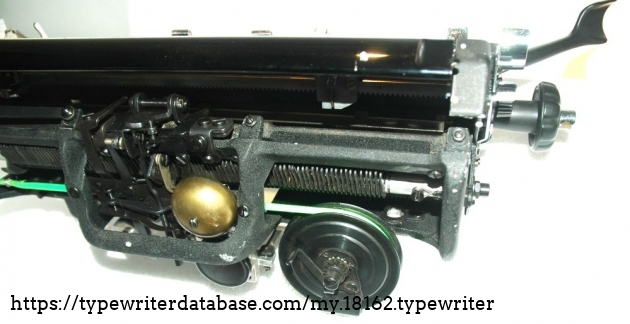

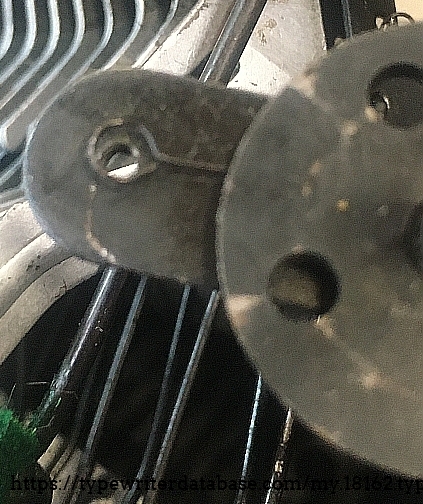

The ink ribbon is not transported in a continuous flow. There is a small jerks at every keystroke, both of the ribbon transport and the ribbon hopper, especially for the red colour. Now, if the giving ribbon spool turns completely frictionless, a ribbon loop will develop at the giving spool by its inertia. So, a good design provides a little bit of friction on purpose, over the natural friction that you cannot rely on. The Hermes Ambassador is an elaborate example. This Everest ST specimen had a wire spring pinching the right-hand spindle (see photo). On the left spindle, this spring got lost. A donor machine ST (#224337) had an eyebrow-raising design: the piece of cloth was wrapped around the spindle assembled freely with a tension spring (see photo). It is now in the #210407

The carriage is a self-contained functional element that can be taken from the machine after removing two knurled nuts. Re-positioning is easy.

The long levers at the right side of the carriage are a bit of a nuisance since they are in each other’s way. The longer lever serves to set and to clear a tab. The tab button is an aluminium pushbutton, to the right of the ‘firewall’ (with the logo).

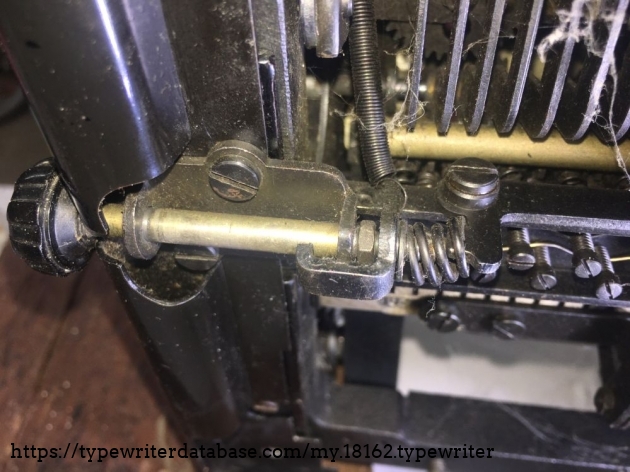

The carriage has an escapement and a nice friction brake (see photo) that limits the speed at which the carriage moves to the left after pushing the tab button. Small detail: you must let the carriage move freely until it hits the stop, because it is only then that the friction-brake is decoupled. If you stop the carriage by hand you will have to move it against the friction.

This ST has a Dutch keyboard, with an ‘ij’ (as in weight) and an ƒ (from florijn, for guilder. The is no hash #. The machine has 10 cpi and large letters. The ruler that carries the two small cork paperrollers is from the donor-machine 224337. It has 12 cpi but its chrome shines irresistibly better. The 10cpi ruler is kept for those who prefer originality.

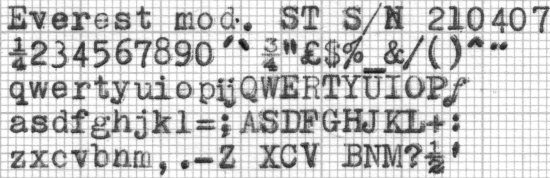

Typeface Specimen:

Photos:

Hunter: Hein Reinders (heinemaat)

Hein Reinders's Typewriter Galleries [ My Collection ] [ My Sightings ]

Status: Typewriter Hunter

Points: 1145

As a retired product development engineer, I am fascinated by the design of electro-mechanical products in which parts move, make noise and, preferably, radiate a little heat. Most preferred are products that are operated by keys, like typewriters, accordeons and pianos.

My genetics and statistics on lifetime expectancy suggest that it is time for me to let you know about the fantastic design, product engineering and manuacturing skills of the generation before mine. I salute mr. Munk for the opportunity that he has created for me to show it to the world. Okay, a bit bombastic.

Comments? Email me at hreinder1950@gmail.com

RESEARCH NOTE: When researching the Everest ST on a computer with lots of screen real estate, you may find that launching the Everest Serial Number page and the Everest ST By Model/Year/Serial page in new browser windows can give you interesting perspectives on changes throughout the model series.