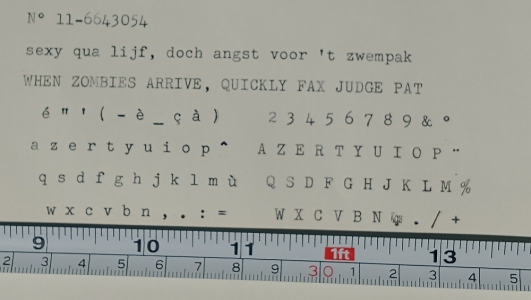

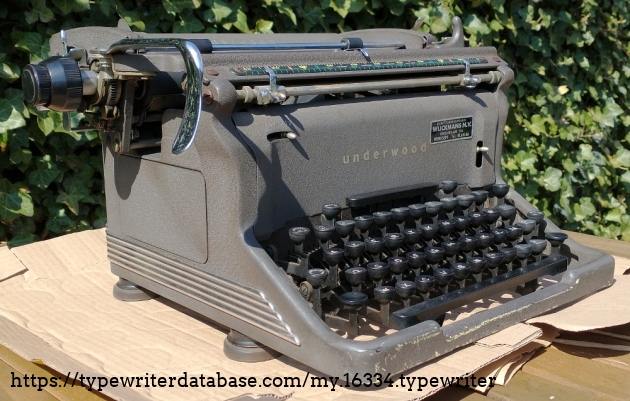

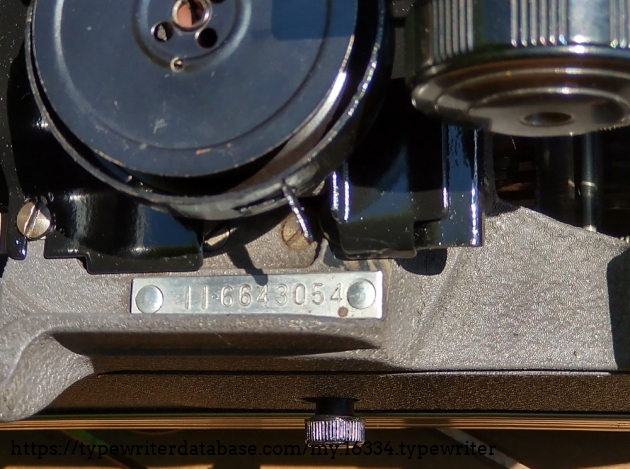

1950 Underwood Rhythm Touch #11-6643054

Status: My Collection

Hunter: Kevin Stallaert (KStallaert)

Created: 07-05-2021 at 12:37AM

Last Edit: 07-05-2021 at 01:09AM

Description:

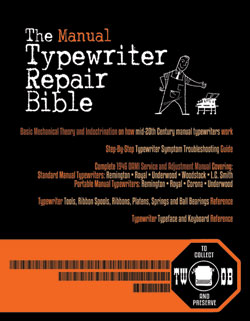

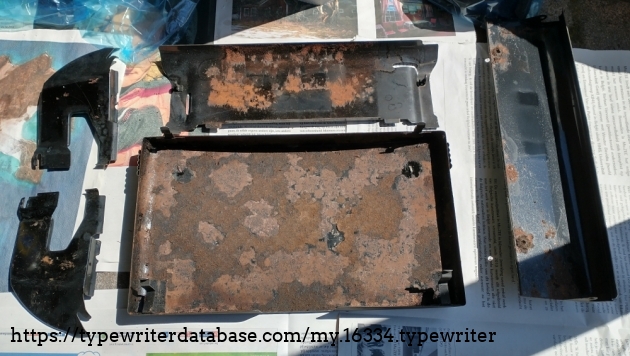

This is the first typewriter I bought that I needed to to do some serious work on. The previous owner had gotten it from his grandfather. The ad mentioned it was serviced. turns out it was serviced... 30 years ago. The add had been up for several months, and claimedthat the typewriter was in working condition. I can only guess that the previous owner WD40-ed the machine completely when he originally put it up for sale. The keys were gunked and gummed up so bad that they didn't come back down . Even the basket didn't return to it's "up" position when the shift was released. Locked up margin selectors, serious rust beneath the sound dampening insulation, yellow paint on the front... I learned a lot of new skills with this machine. I had to replace some keys because they had cracked and a spring because it had completely worn out.

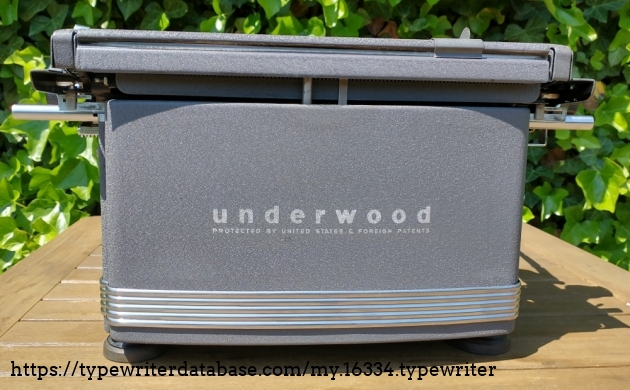

It was a lengthy restoration, but now it is shiny and chrome again. And a bit mediocre too, because my home made concoction (water, window cleaner, soda crystals and a drop of dishwashing soap. No simple green available in Europe) was good to get the thick greasy layer of dirt off, but wrecked havoc on the decals. II added some pictures of my bad decals so you can learn what definitely not to use when restoring these machines. I probably could have done better if I had some very fine permanent markers.

Another thing that took a lot of time was getting the yellow paint in front off. I scrubbed it with a toothbrush and some WD40. Then I got to work with a metal dentist pick, carefully scratching the yellow paint, following the ridges and crevices of the crinkle paint, scrubbing it again, fresh WD40, etc. That took me about half a day.

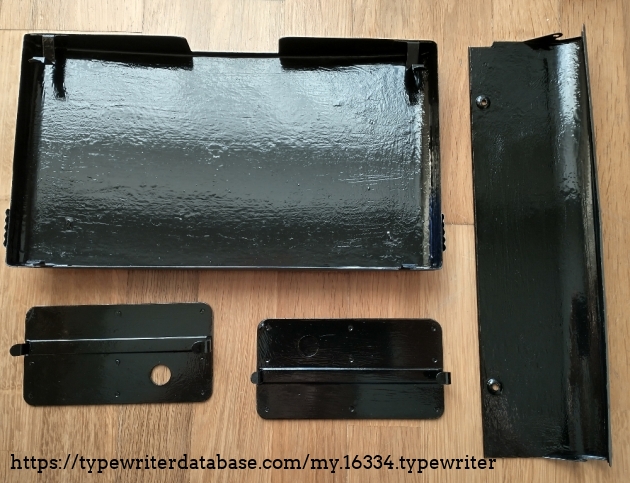

I wish I could find the exact RAL color somewhere, but since the base coat beneath the crinkle paint is black, I used glossy Hamerite on the exposed (previously painted) bare metal parts. The non-visible parts and small exterior things where done with a brush, the visible part of the dust catchers beneath ribbon holders where done with a can of Hamerite spray paint.

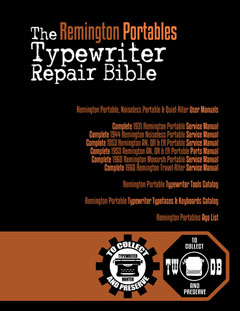

This machine and my parts machine came with two different metal spools. This is probably because the manual (see link, last page) basically suggests to install a new full ribbon spool, and attach the new ribbon to the old empty ribbon spool.

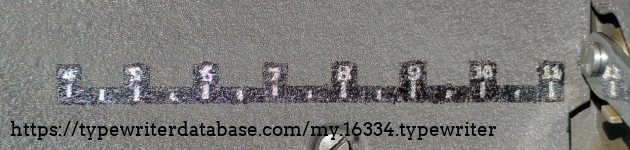

Now this piece of industrial design with chrome trims normally found on beautiful cars works again (the sound of that brass bell is wonderful). I think it used to be an inventory machine, because it has two custom slugs: one with 2 "." instead of a dot and a semicolon, and one slug that is cut in half to add a "kgs" part instead of a question mark. So this is a "no-questions asked" machine.

Only one more thing to do: add some new noise dampening insulation. Now it sounds like a toddler banging on a tin when your are typing.

Typeface Specimen:

Links:

Photos:

Hunter: Kevin Stallaert (KStallaert)

Kevin Stallaert's Typewriter Galleries [ My Collection ] [ My Sightings ]

Status: Typewriter Hunter

Points: 1089

I fell into the typewriter rabbit hole due to nostalgia: I used to have a massive Olympia SG1 when I was a kid. It formed my typing habits, which is why I am called a "furious typer" by my coworkers. Came across the r/typewriters page on Reddit which rekindled my love for these wonderful machines. Lets just hope I don't start pushing screens off my desk when I reach the end of a line...

I also have a modest Youtube channel where I document the progress of my typewriter journey: https://www.youtube.com/@Slug_Life

RESEARCH NOTE: When researching the Underwood Rhythm Touch on a computer with lots of screen real estate, you may find that launching the Underwood Serial Number page and the Underwood Rhythm Touch By Model/Year/Serial page in new browser windows can give you interesting perspectives on changes throughout the model series.